Servo Tester

This handy little gadget has a range of uses, but is particularly useful for checking that a servo is working properly and also when setting up a servo in a loco to check that it will do its job properly. It can also be used to check an ESC (electronic speed controller).

A tour of the tester

Setting up the servo tester.

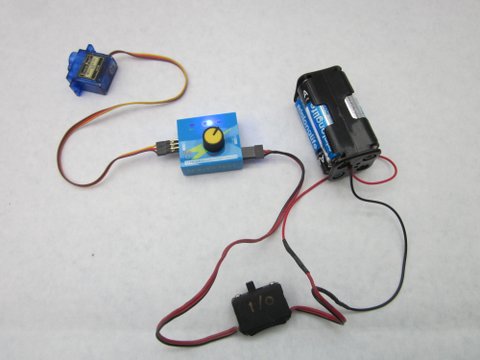

The servo tester needs a power supply. It works with voltages between 4.8v and 6v and so a battery box with four AA cells (alkaline or NiMh) is ideal. I use one designed for use with receivers which includes a switch and a standard JR connector.

Attach the power connector to the pins on the right hand side of the tester. One of the LEDs should light up to show it is powered up and ready.

Connect a servo to one of the three sets of pins on the left hand side of the tester.

Up to three servos can be connected. They will all respond to the instructions sent by the tester, which is useful for comparing whether a servo is behaving the same way as others if you are not sure if a servo is faulty.

Modes

The Tester has three modes: Manual, Neutral and Auto. To change from one mode to the other, press the button on the bottom left corner of the tester and the unit will change from one mode to another, shown by the LEDs.

A tour of the tester

Setting up the servo tester.

The servo tester needs a power supply. It works with voltages between 4.8v and 6v and so a battery box with four AA cells (alkaline or NiMh) is ideal. I use one designed for use with receivers which includes a switch and a standard JR connector.

Attach the power connector to the pins on the right hand side of the tester. One of the LEDs should light up to show it is powered up and ready.

Connect a servo to one of the three sets of pins on the left hand side of the tester.

Up to three servos can be connected. They will all respond to the instructions sent by the tester, which is useful for comparing whether a servo is behaving the same way as others if you are not sure if a servo is faulty.

Modes

The Tester has three modes: Manual, Neutral and Auto. To change from one mode to the other, press the button on the bottom left corner of the tester and the unit will change from one mode to another, shown by the LEDs.

Manual.

This is probably the most useful mode. When in this mode, the servo(s) will move in response to the position of the control knob. Twist the knob and, if all is well, the servo arm will move in response.

Neutral

Putting the tester into this mode will centre the servo. This is useful for checking whether the servo (or ESC) returns to its correct central position.

Auto

In this mode, the servo will move from left to right and back again automatically, in a similar way to windscreen wipers. This is useful when setting up a servo to ensure that the linkages connected from the servo to, say the regulator, have been adjusted to give a full sweep.